Electric Drive Solutions for Aerospace & Defense

Plettenberg is a leading developer and manufacturer of rugged electric drive solutions for aerospace & defense applications. Looking for a reliable electric drive solution for your project?

When your drive system has to work...

Plettenberg electric drive solutions are unrivalled in their reliability, power-to-weight ratio, efficiency and compactness, making them suitable for aerospace applications and defense missions in the harshest environments.

What we offer

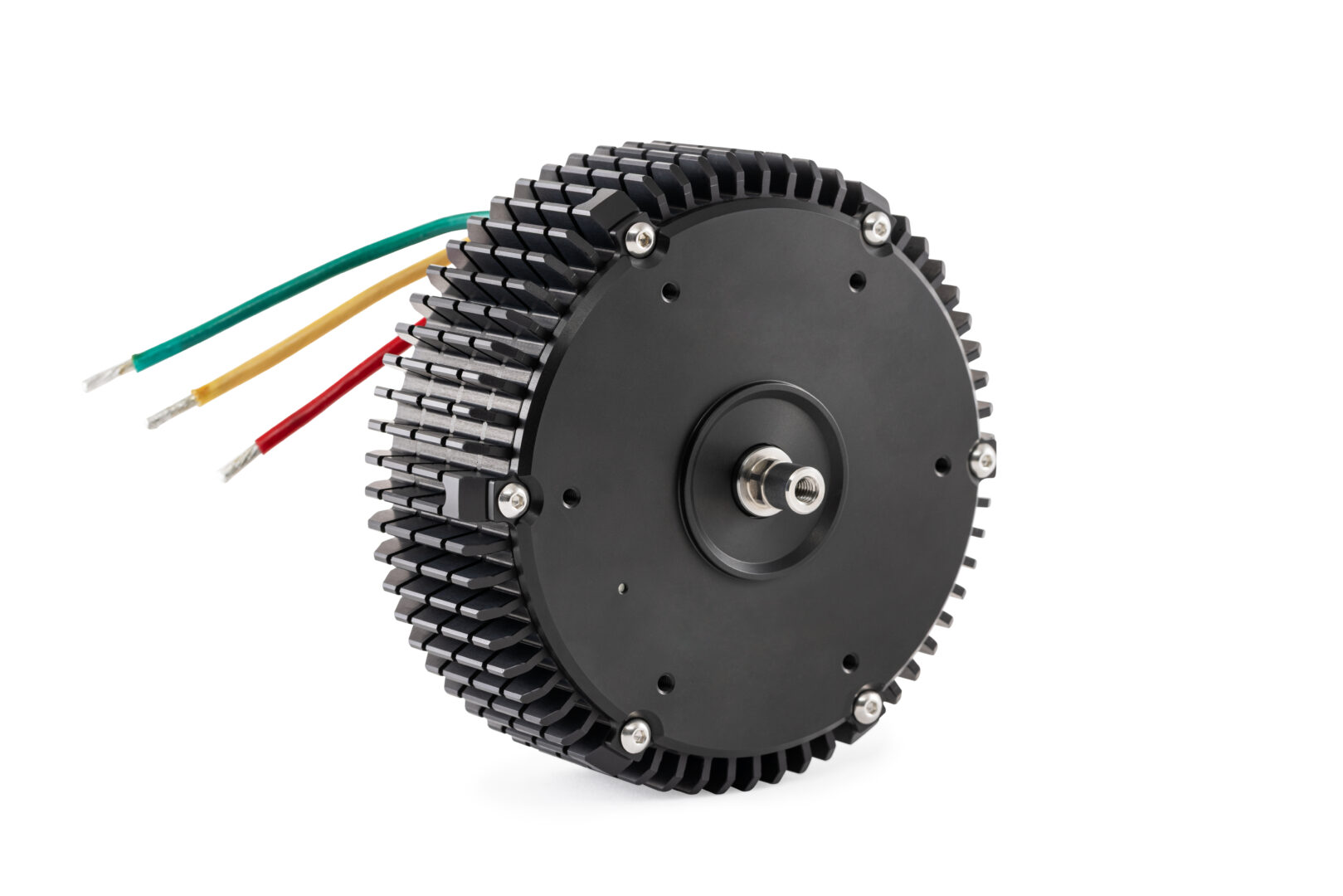

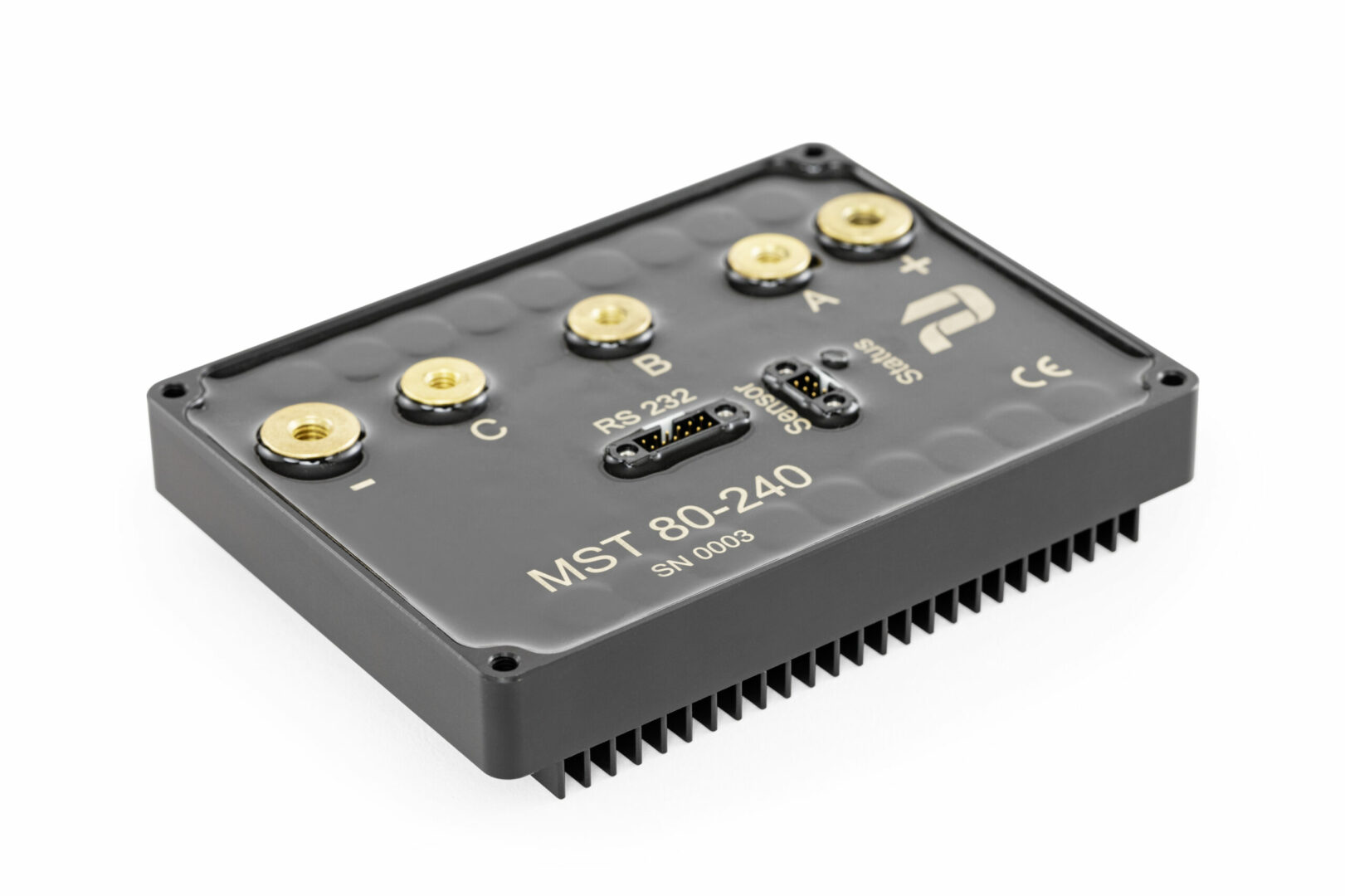

Our product portfolio comprises rugged inrunner and outrunner BLDC motors, brushed DC motors, ESCs, starter and generator systems as well as mission critical accessories. Our products are designed for application in the harshest environmental conditions and many of our COTS/standard products are already qualified to MIL-STD 810H. This allows for achieving the best reliability and minimizing total-cost-of-ownership.

Our products are offered as COTS, MOTS and fully custom solutions. Our engineering team works hand-in-hand with our customers to develop the best possible solution and provide comprehensive system integration support. We can also design our systems according to specifications. Our products are ITAR free and NDAA compliant.

COTS

Our commercial-off-the-shelf (“COTS”) drive solutions have been designed to cover a wide range of applications in demanding end-markets. Our portfolio of more than 30 COTS standard motors comprises rugged inrunner BLDC motors from our NOVA and ADVANCE series as well as outrunner BLDC motors from our ORBIT series. Datasheets for all COTS motors are available. Lead times for our COTS motors are typically ~4-6 weeks.

MOTS

MOTS (“modified-off-the-shelf”) motors have the same mechanical parts as COTS motors but come with a customized winding. The winding of the motor determines the Kv (rpm/V) and allows for adapting the motor to the application requirements. Plettenberg offers MOTS motors with electrical design support from our engineering team, including an engineering study, which covers data sheets and performance simulations.

Fully Custom

If a MOTS solution is not sufficient and significant tailorization is required, a FC (“fully-custom”) solution is the best choice. FC drive solutions are often highly application specific and adjusted to complex requirements. Examples of customization options include:

- Application specific housing and shaft adaptation

- Special cooling systems with active or passive fans and/or ducts

- Special materials for aerospace or maritime applications

- High ingress protection class up to IP67

- Compliance with MIL-STD 810 or RTCA DO-160 requirements

- Special wrapping of magnets for high rpm applications

- Redundant winding solutions

- Frameless stator / rotor solutions

- Single line replaceable units with integrated ESC

- Custom MIL-STD connectors

- Customized generator and starter systems for hybrid applications

Plettenberg has more than 40 years of motor design and manufacturing experience, with proprietary design and simulation tools, which utilize a huge database of actual dyno measurements. This allows for highly accurate performance and thermal simulations of custom motor designs.

From our experience, most projects start with a COTS or MOTS solution, and progress to FC solutions as first data has been gathered and requirements become more rigid.

We are available to support you

We provide comprehensive engineering support and help our customers to find the ideal drive solution for their A&D project.

If a COTS/MOTS drive system is not suitable, we propose a customized drive solution. This can lead to efficiency improvements of 15-30% at comparable size and weight.

System engineers are often confronted with trading off weight vs. robustness / reliability. Our products are all rugged in design (max. IP67) and specifically developed for application in the harshest environments. At the same time, our products are weight optimized in design and provide the best weight-to-robustness ratio.

Our support covers the entire product life-cycle. We start with designing the product according to complex specs (build-to-spec). Next, we perform qualification of prototypes (incl. MIL-STD 810 and RTCA DO-160) and support the certification process. Following successful integration, we act as partner for serial production and support spare parts and repair services for an unlimited period of time.

Recommended Products

BLDC Inrunner

Plettenberg is the global leader in high-performance inrunner BLDC motors.

Generators

Generators & starter systems. Up to 15kW.

BLDC Outrunner

Plettenberg is a leading provider of high-performance outrunner BLDC motors.

ESCs

Controllers / inverters. Up to 400 V and 350 A.

Aviation Design & Plettenberg UAV Propulsion System

Plettenberg providesthe electric propulsion motor for the Spy Ranger UAV of Aviation Design

The Challenge

Aviation Design is a leading developer and manufacturer of UAVs, aerial targets, sub scale demonstrators and wind tunnel models for defense and civil applications. The company produces drones under license for major aerospace companies and is authorized by the French Ministry of Defense for building and marketing defense products. One of the flagship projects is the Thales Spy Ranger Program, a contact airborne intelligence, surveillance and security UAV system. The Spy Ranger was selected by the DGA to be operational for the French army. Aviation Design was looking for a highly robust, light weight and efficient propulsion system for the Spy Ranger. The electric motor had to be able to operate in harsh conditions, such as high altitude and extreme weather conditions, including snow and rain. The efficiency and power-to-weight ratio was also very important to support extended flight ranges.

FAQ

Plettenberg provides COTS/MOTS and fully customized drive systems. All our products are manufactured on a made-to-order basis. Hence, we do not have a stock of products. Our lead times depend on the required engineering and customizations efforts. Most products can be delivered in a 4-12 weeks timeframe. Please reach out to our sales team for more information on our lead times.

Please reach out to our sales team for a quotation for our COTS and MOTS products. For fully custom solutions, we can provide a ROM pricing, after we have evaluated all requirements.

We need detailed information on your application, such as targeted voltage, current, rpm, load profile data, ambient conditions, cooling, altitude, etc. If certain data points are not yet available, we will support you. Please reach out to our sales team and we provide you with a spec sheet.

Our engineering team provides comprehensive electrical and mechanical design support throughout the entire development phase. This is complemented with best-in-class project management, to make sure that all deliverables are provided on time and quality throughout all phases of the project. Please also refer to the “Process” section of our website for more details on a typical FC project.

We can perform several MIL-STD 810 tests in our inhouse lab but also work with external test labs (e.g. for MIL-STD 461/810 and RTCA DO 160). All our operations are set up according to aerospace standard and our quality system is EN 9100:2018 certified.

All products are 100% developed and manufactured at our HQ in Germany according to the highest quality standards. We only use the best raw materials and components from suppliers with domiciliation in Europe or the US.

We support platforms for air, land and sea missions, both crewed and uncrewed. We have specific product platforms for each use-case and are happy to provide additional information upon request.

Yes, we provide a wide range of frameless motor products (stator, rotor) in various configurations. We also provide inverters as frameless PCBs upon request.

Ready for a rugged drive system for your A&D application?

Please reach out to us and our engineers will evaluate your project for potential optimization.