Electric Motors

Plettenberg provides a wide range of electric motors for mission critical applications.

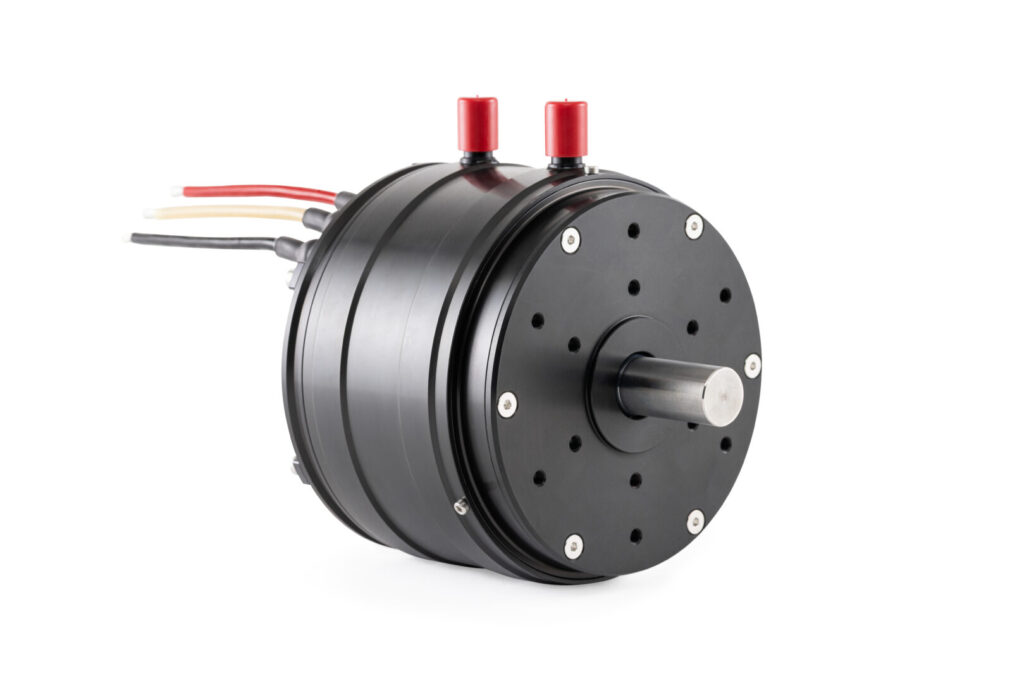

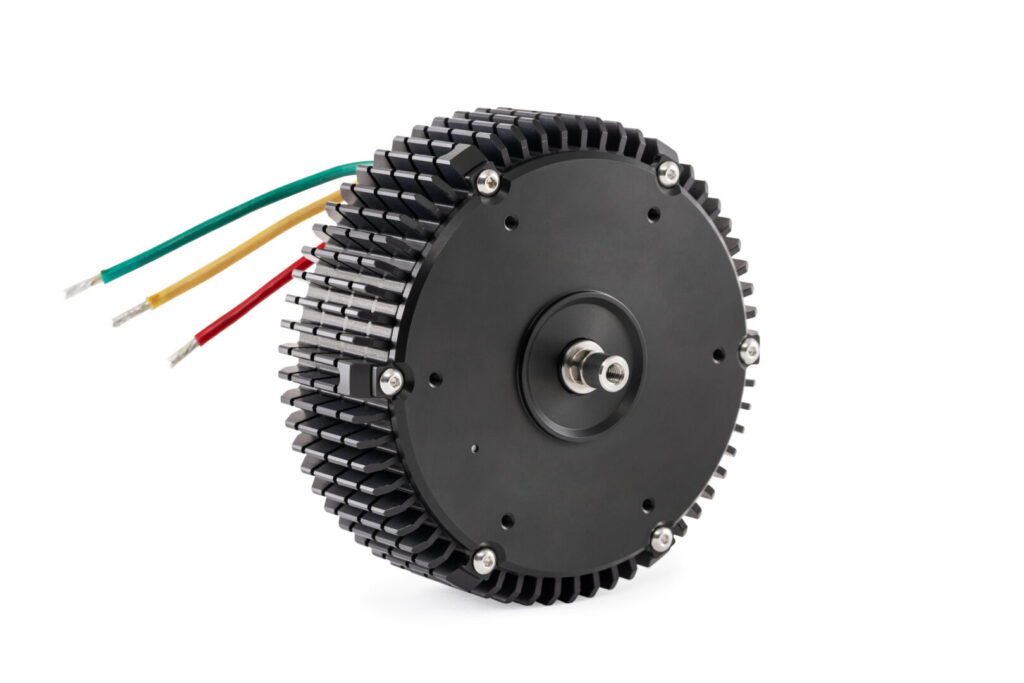

We are the global leader in ultra-rugged high-performance inrunner BLDC motors. Our portfolio also includes outrunner BLDC motors, brushed DC motors and starter & generator systems.

All our motors are developed and manufactured at our HQ in Germany according to highest quality standards.

COTS

Our commercial-off-the-shelf (“COTS”) drive solutions have been designed to cover a wide range of applications in demanding end-markets. Our portfolio of more than 30 COTS standard motors comprises rugged inrunner BLDC motors from our NOVA and ADVANCE series as well as outrunner BLDC motors from our ORBIT series. Datasheets for all COTS motors are available. Lead times for our COTS motors are typically ~4-6 weeks.

MOTS

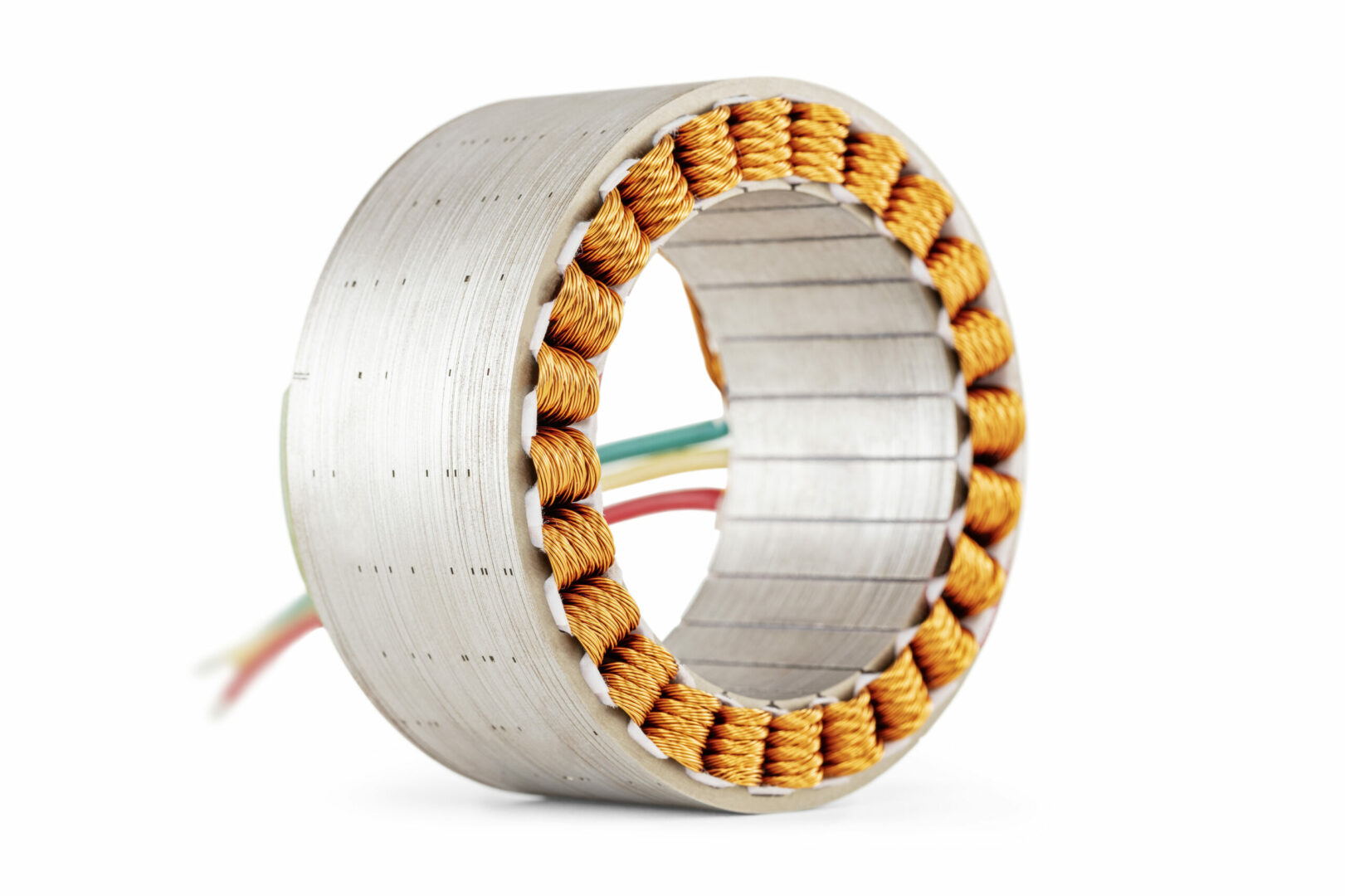

MOTS (“modified-off-the-shelf”) motors have the same mechanical parts as COTS motors but come with a customized winding. The winding of the motor determines the Kv (rpm/V) and allows for adapting the motor to the application requirements. Plettenberg offers MOTS motors with electrical design support from our engineering team, including an engineering study, which covers data sheets and performance simulations.

Fully Custom

If a MOTS solution is not sufficient and significant tailorization is required, a FC (“fully-custom”) solution is the best choice. FC drive solutions are often highly application specific and adjusted to complex requirements.

Plettenberg has more than 40 years of motor design and manufacturing experience, with proprietary design and simulation tools, which utilize a huge database of actual dyno measurements. This allows for highly accurate performance and thermal simulations of custom motor designs.

From our experience, most projects start with a COTS or MOTS solution, and progress to FC solutions as first data has been gathered and requirements become more rigid.

Our BLDC Inrunner

Our Brushed DC

Ready for an electric drive system tailored to your use case?

Other product types

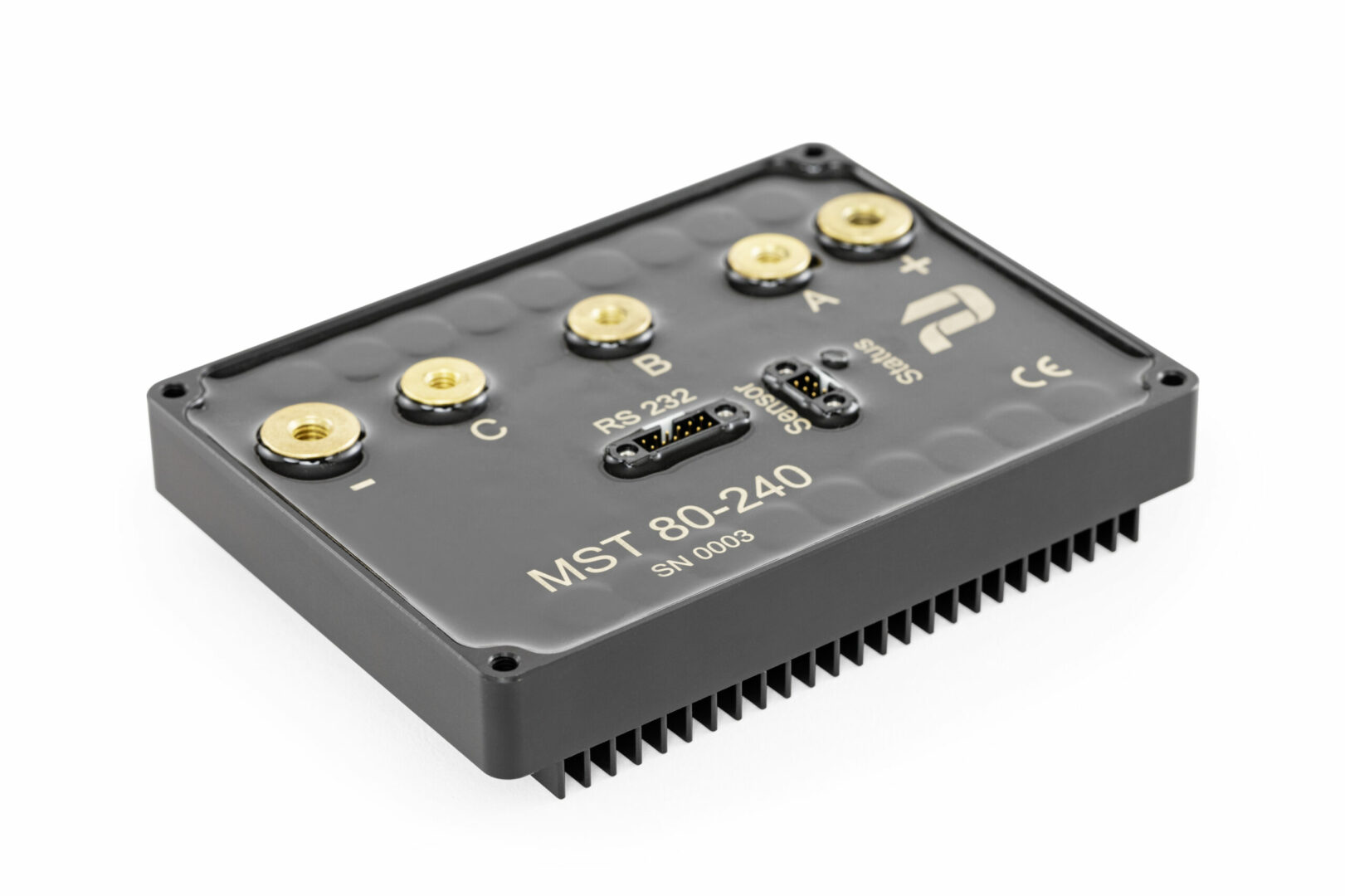

ESCs

Electronic motor controllers. Up to 400 V and 350 A.

Generators

Generators and starters. Up to 15kW.

Accessories

High-quality, low weight accessories.